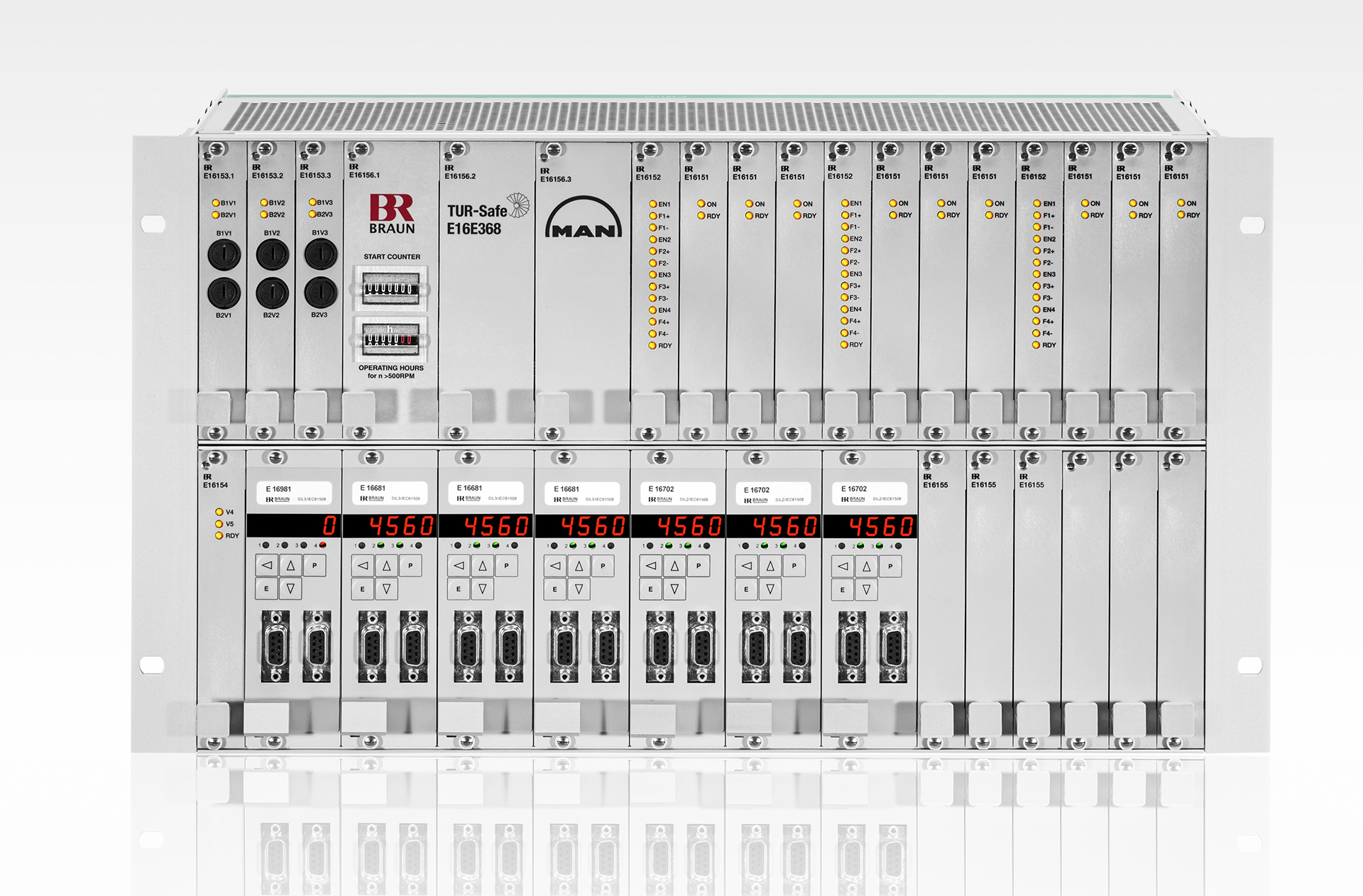

E16E368 (MAN Energy Solutions)

Monitoring and Protection System E16E368 for highest safety requirements up to SIL3

The BRAUN High Safety Protection System Series E16E368 is TÜV certified for SIL3 acc. IEC 61508:2010 and is API 670 Ed.5 and API 612 Ed.7 compliant. It provides protection against overspeed and detects reverse direction. Also up to six other trip criteria, such as emergency stop, boiler protection, etc. can be included in the trip string.

Due to its globally unique and true 2oo3 architecture, the system will tolerate one faulty signal within each trip criterion without trip being released.

The TMR (Triple Modular Redundancy) design ensures highest safety and availability for the monitored machine, i.e. the system will bring the machine into a safe state once it has reached a critical condition.

The E16 Protection System consists of three Monitors E16681 for the evaluation of speed and external trip signals, one Test Generator E16981, different additional modules and a system backplane; all mounted into a 19” rack.

The E16 Protection System permanently monitors the speed sensors for their correct function. During its useful lifetime of 20 years, the system does not require any external proof tests. It is completely maintenance-free and therefore has minimized TCO (Total Cost of Ownership).

All active components (including the trip relays) are directly located on the Monitors and thus can be replaced during operation. The protection system offers in total six 2oo3 Trip Outputs, thereof three for a solenoid trip block and three for other purposes.

Key Features

- SIL3 / IEC 61508:2010 certified

- API 670 Ed.5 compliant

- API 612 Ed.7 compliant

- Total Response Time to Trip < 15 ms

- Useful Lifetime and Proof Test Interval = 20 years

- Triple speed measurement and monitoring by each Monitor

- Variable Overspeed setpoint depending on acceleration

- Direction detection

- Evaluation of external Trip Criteria signals by up to 6 voters per Monitor

- All Trip Outputs formed with safety relay contacts in 2oo3 technique

- Trip Output Monitoring to solenoid with Trip-Lock

- Up to 5 additional speed setpoints in 2oo3 technique

- Sensor signal repeater outputs, free-floating, and push/pull

- Automatic test and monitoring of 2oo3 solenoid trip block

- The only protection system worldwide where all relays or other active components are located on the Monitors

- 2 PROFIBUS Interfaces

- Additional features for E16E368 MAN

o Up to 12 load outputs with 2oo3 technique for E/H-Converter or valves

o 30 additional digital inputs for 10 digital trip criteria

o 15 additional analog inputs for 5 analog trip criteria

o Last Blade Protection

o Counters for number of starts and hours of operation

Benefits

- Maintenance-free during Lifetime, therefore minimized TCO

- Highest safety at maximum availability due to true 2oo3 architecture for each trip criterion within each Monitor

- Extremely low PFD value (Probability of Failure on Demand), less than 1% of allowable value for a SIL3 loop

- Replacement of all active components during operation possible (hot swap and highest availability)