The high expectations of our customers provide the incentive for our activities

Our major OEM customers have precise requirements to ensure overspeed protection and other trip criteria for their rotating equipment and turbomachinery, such as turbines, compressors, and expanders.

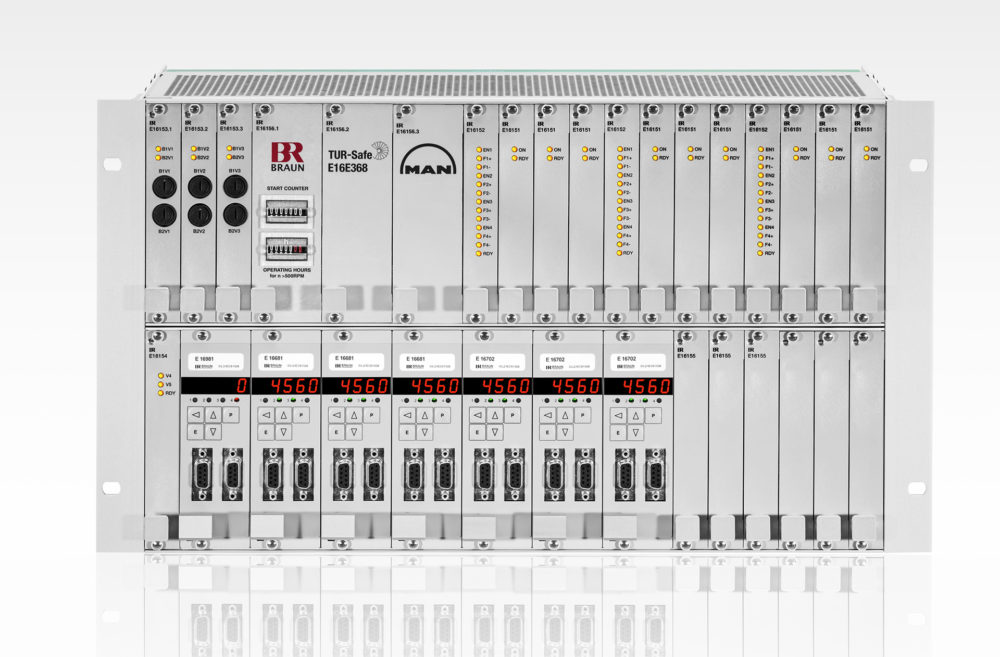

Our high level of development competence and close partnership with our customers ensure the perfect implementation of those requirements. Therefore, we produce OEM-specific protection systems with the highest standards.

With their TMR architecture, BRAUN Protection Systems monitor equipment relevant to safety, such as can be found in the power generation industry, thereby guaranteeing its trouble-free operation. Our worldwide unique and true 2oo3 architecture – for each trip criterion within each Monitor – delivers the best protection and avoids unnecessary trips with simultaneously maximum machine availability. Furthermore, many integrated and sophisticated function tests are carried out fully automatically during operation, thus guaranteeing the constant availability of the protection system.